After the Recycling Bin

With all the talk about recycling, do you know what those numbers on your plastic containers mean? Recycling is a great way to reduce demand for plastics, but it’s not as simple as putting your bottles in a blue bin. Different kinds of plastics are created for different purposes, and post-consumer plastics need to be managed in different ways. To improve recycling’s efficiency, consumers need more information about the process by which plastic is recycled.

What Goes Where

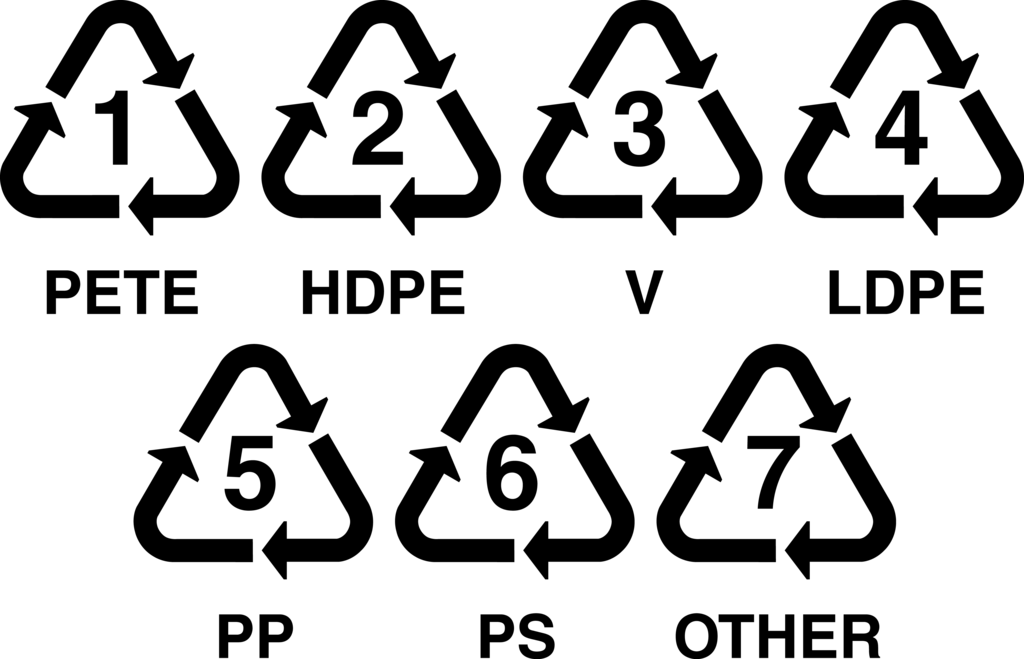

Identifying the resin code is the first step in properly recycling plastic. Most recycling facilities can only process types 1 (PET), 2 (HPDE) and recently 4 (PEBD) and 5 (PP). As a consumer, most of the commercial plastics you use are type 1 and 2, which makes things easier. However, there are many everyday plastics (labeled 3, 6 and 7) that cannot be recycled. Plastics numbered 7, for example, are mixed composition or bioplastic and if recycled, may contaminate and prevent the reuse of type 1 plastics. Thus sending no 7 plastics to a landfill is a better option. While plastic grocery bags are indeed recyclable (typically in bins at grocery stores), they cannot be recycled in traditional facilities because they get caught in sorting machines. The sorting machines have to be shut down and cleaned and that reduces the overall efficiency of the operation. It is best to identify the number listed on the plastic you are recycling and find out what your local center accepts. Check out NYC’s list of what is recyclable.

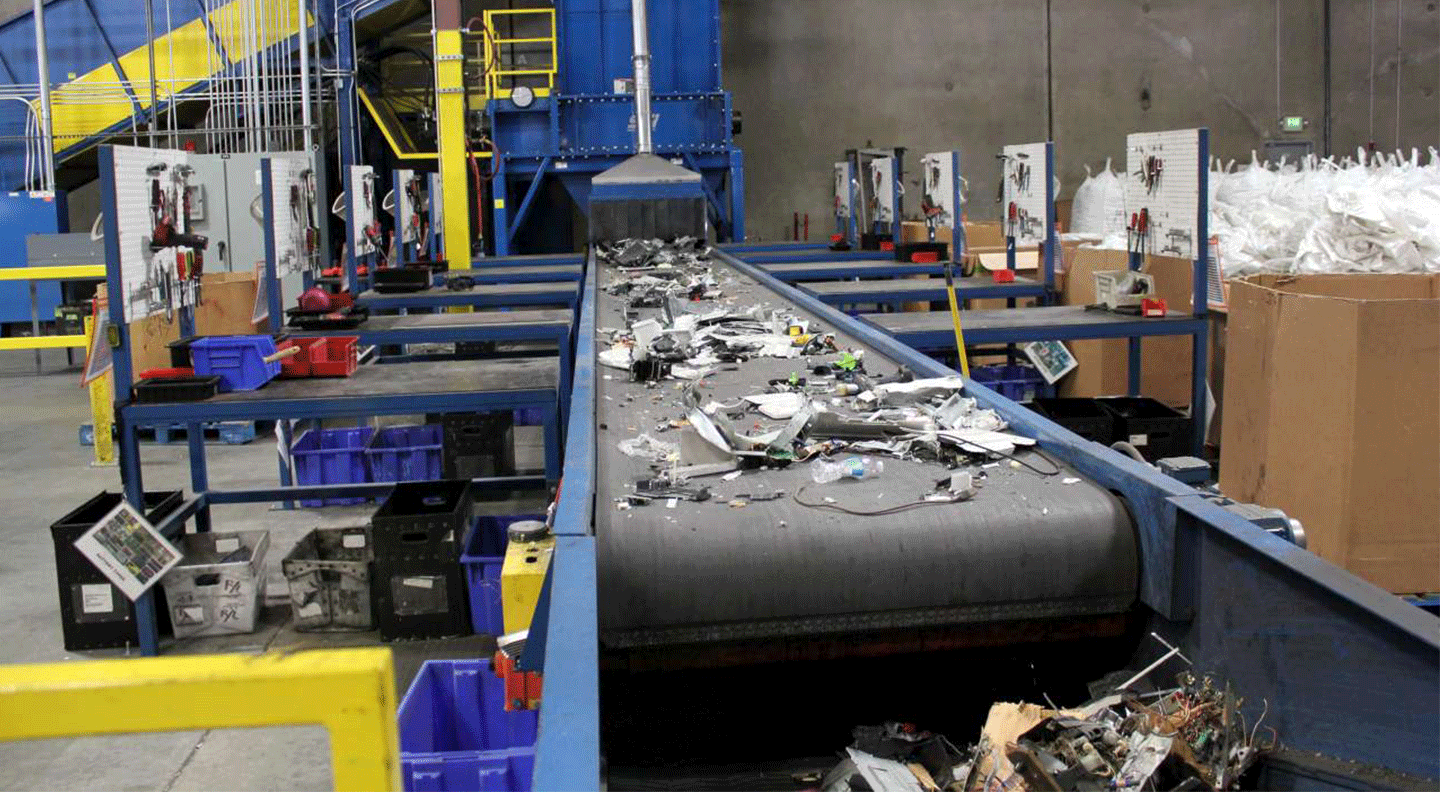

Much of New York City’s recycling is processed by Sims Municipal Recycling at various centers throughout the boroughs.

The Recycling Process

If your plastic is recyclable, it goes through a 6 stage process before it can be repurposed. Many major cities have adopted single stream recycling (NYC hopes to transition by 2020), whereby all glass, metal, paper and rigid plastics are sent to the facility together. The materials are then sorted by machines based on material type, and plastics are specifically sorted by type and color (as dyes complicate the process). There are traditionally three streams for plastics: clear PET, green PET, and non PET. The bottles are compressed into bales before they are broken and washed. The plastic is washed to remove impurities (things like food waste, labels and bits of metal) that would compromise the structural integrity of the final product. Following a good wash, the plastic is shredded into tiny particles which increase the plastic’s surface area and manageability. The tiny plastic particles are then further separated by density and size. Less dense plastic floats and denser plastic sinks (think water bottles – the bottle (1) will sink while the bottle cap (5) will float). On top of that, there is an air classification test which determines how thin the particles are. Finally, the particles are compounded together; the plastic is melted and extruded into spaghetti-like strands, cooled, and chopped into pellets. These pellets can then be used to make plastic lumber, buckets, pots, clothing, fibers and more. This video courtesy of Avery Dennison shows a little bit more of the process.

Of the 35.4 million tons of plastic generated, only about 3 million tons were recycled in 2017, according to the Environmental Protection Agency. As recycling is made easier thanks to single stream systems and recycled plastics are used more frequently, we can reduce the plastic ending up in our landfills. However, in addition to recycling the plastic, we must strive to decrease the demand for plastic by reducing and reusing what we have.